By Arshdeep Gill, PhD Candidate, Kizhakkedathu lab

By Arshdeep Gill, PhD Candidate, Kizhakkedathu lab

“Biomimicry,” the ability to replicate the functions of biological molecules with synthetic analogs, is one of the longstanding goals in both science and engineering. In particular, macromolecules (synthetic globular polymers with molecular weights >1 million Daltons) offer a plethora of opportunities to replicate biological molecules.

One of the potential avenues for biomimicry with macromolecules is replicating synovial fluid. Synovial fluid has a high viscosity, a fancy term used to measure the ability of a liquid to flow; in other words, it describes the “thickness” of a fluid (for example, honey has higher viscosity than water). Intact synovial fluid is critical for lubricating joints in the human body. It prevents the cartilage covering the bones at the joints from being damaged by friction caused by everyday movement. However, in certain arthritic diseases, such as osteoarthritis, the viscosity of the synovial fluid is altered when the synovial fluid is degraded over time.

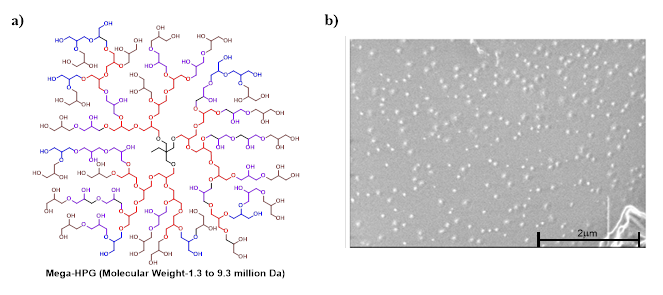

Figure 1: a) Chemical Structure of hyperbranched polyglycerols (HPG) b) Cryo-electron microscopy of mega-HPGs

The greatest challenge in creating synovial fluid-like synthetic analogues is the ability to create macromolecule polymers with the required physical properties. It’s quite difficult to synthesize polymers that are millions of Daltons in size while maintaining high water solubility, biocompatibility, and low intrinsic viscosity. These properties are required to create soft, nanometer sized particles that can act as lubricating molecules with low friction coefficients.

An international team of scientists led by CBR Principal Investigator Dr. Jayachandran Kizhakkedathu, Dr. Mark Grinstaff (Boston University), and Dr. Janne T. A. Mäkelä (University of Eastern Finland) published the first report of synthesizing globular polymers with molecular weights of ranging from 1 to 9 million Daltons with unexpected characteristics that could be used as lubricants1. The scientists called these polymers “mega hyperbranched polyglycerols (mega-HPGs)” due to their branching nature; however, as visualized by cryo-electron microscopy (Figure 1b), and despite their large molecular weight and branches, they form quite compact spherical single particles (20-50 nm in diameter). Furthermore, these mega-HPGs also possess low intrinsic viscosities independent of their molecular weight (Figure 2a). This is a significant advantage because, traditionally, the viscosity of the synthetic material increases with molecular weight, which results in very rigid materials if the molecular weight is high. Thus, these mega-HPGs are unique in that they are of a high molecular weight but are small in size and have a low intrinsic viscosity.

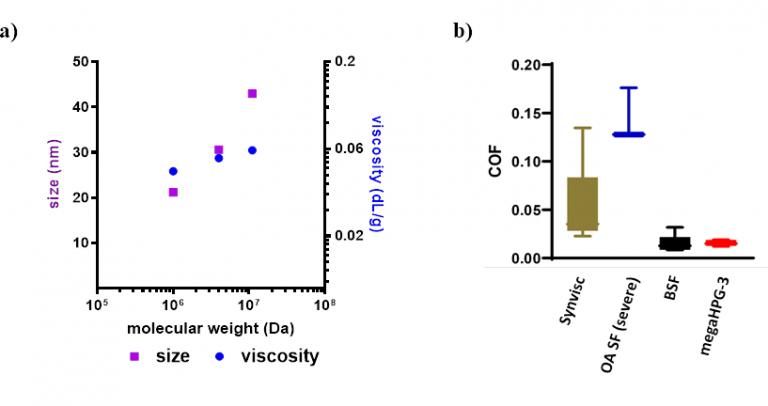

The lubricant properties of these molecules were assessed on hard and soft surfaces. This was done by coating two surfaces with lubricating solutions containing mega-HPGs or other polymers, pressing them together, and sliding them past one another to assess the coefficient of friction (COF). The COF is used to describe the “slipperiness” of a surface. For instance, an ice rink has a lower COF than a gravel field. Dr. Kizhakkedathu’s team found that one of the mega-HPGs, mega-HPG-3 (3 million Dalton HPG), had a COF that was an order of magnitude lower than those of synthetic polymers found in the literature, such as Synvisc (a solution of hyaluronic acid used currently in the hospital to treat osteoarthritis) (Figure 2b). Furthermore, mega-HPG-3 had COFs similar to natural healthy bovine synovial fluid (BSF). You can also see that osteoarthritis synovial fluid control has very high COF (blue, Figure 2B) Synvisc. In a practical setting, this lower viscosity of these mega HPGs is advantageous because they can be injected with a 25-gauge needle rather than the 18-gauge needle used for Synvisc, resulting in less painful injections and less damage to the tissue. These results are promising enough to warrant future studies, possibly in clinical settings. How do these mega-HPGs have lubricating properties? The team hypothesized that due to the unique spherical single particle nature and exceptional hydration of mega-HPGs, they can act as ball-bearings to reduce the COF between natural surfaces.

These mega-HPGs showcase how recent advances in synthetic polymer chemistry offer viable tools to help generate large polymers with surprising properties. The work done by the Kizhakkedathu lab and collaborators have further propelled our capability to not only understand complex biological interactions in synovial fluid and other areas, but also to accurately mimic such materials with synthetic macromolecules.

Figure 2: a) Size and viscosity comparisons of mega-HPGs. b) Box and whisker plot of friction coefficient comparisons. Synvisc is a synthetic lubricant used in osteoarthritis. Error bars represent maximum and minimum measurements. Abbreviations: OA SF = osteoarthritic synovial fluid; BSF = bovine synovial fluid; megaHPG-3 = 3 million Dalton HPG.

Reference

1 Anilkumar P, Lawson TB, Abbina S, et al. Mega macromolecules as single molecule lubricants for hard and soft surfaces. Nature communications. 2020;11:2139-9.